Purpose built factory

Our new factory has been designed and arranged internally to create an efficient production line to allow the company to produce hydraulic cylinders.

Safe & efficient raw material handling

Vehicles delivering raw material can enter the factory in a specific location directly underneath our overhead crane allowing a completely safe and effective handling of the materials into the storage area. From there material is cut to the pre machined lengths and placed into metal work stillages so it can be easily handled through out the production process.

CNC machine tools

The company currently operates 10 CNC machine tools of which 4 are fully automated with robot loaders to allow the machines to run continuously maximizing their production capacity. All the machined parts are checked against gauges and measured for both dimensional as well as geometric accuracy.

Bespoke cleaning & washing facilities

After the machining process all parts are cleaned and washed in our bespoke wash facility, this allows us to load tubes in multiple batches saving time and ensuring that all parts are thoroughly cleaned prior to assembly.

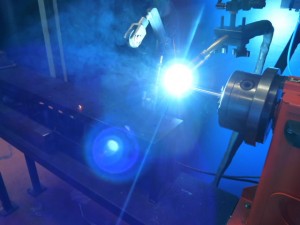

Fully & Semi-automatic welding

Welding is done in 4 areas, we have 2 semi automatic / manual welding areas for the production of more technical products. Alongside these we have 3 fully automated welding processes which include a 6 axis robot welding system for higher volume work.

Assembly & testing

Assembly and testing takes place in a clean environment, because of our integral design of our cylinders the assembly process requires the use of a torque multiplier to screw the piston on to the rod, this also allows us to assemble the cylinders consistently. After assembly every cylinder is tested using pneumatic pressure drop detection system and then engraved with the part number, week and year of manufacture and the works order number for complete traceability. We can also offer a hydraulic pressure test up to 300 bar if required.

Painting & finishing

We also have in house painting facilities for either a primer or full gloss finish.

It’s our company policy to invest in the best machines and processes possible to enable us to produce a high quality product at a competitive price, this policy also incudes finding the most environmentally friendly solution where possible.