Company profile

C & C Hydraulics specialise in the design and manufacture of hydraulic cylinders for specific applications. The company was formed in 1994 and currently employs 30 people. We have supplied equipment into the access industry for 20 years and working alongside our customers, have developed a range of products that provide solutions helping to resolve problems encountered on specific applications.

C & C Hydraulics specialise in the design and manufacture of hydraulic cylinders for specific applications. The company was formed in 1994 and currently employs 30 people. We have supplied equipment into the access industry for 20 years and working alongside our customers, have developed a range of products that provide solutions helping to resolve problems encountered on specific applications.

Opportunity

We were approached by a leading lift manufacturer in the UK to look at the possibility of improving the operation of the telescopic cylinders they were using. The cylinders were a synchronised telescopic design but the customer wanted to add a cushioned landing and a cylinder reset after each cycle. They also wanted to keep the cylinder the same dimensions and foot print, making the room we had internally to accommodate the extra functions very tight.

Solution

Our primary design objective was to create the cushioning system and simulate this operation on our in house vertical testing system. Upon testing we discovered we required a larger cushioned pocket and therefore created an extra oil gallery which allowed the cylinder to open uniformly.

Our primary design objective was to create the cushioning system and simulate this operation on our in house vertical testing system. Upon testing we discovered we required a larger cushioned pocket and therefore created an extra oil gallery which allowed the cylinder to open uniformly.

Our second design requirement was to create the reset system. Initially we did this using a standard cartridge, however at the trial phase we were informed by the customer that the re set system was required even without the cylinder loaded and so we endeavoured to design a special cartridge with a higher pressure rating, this solved the customers problem.

Finally with the cylinder functioning as the customer requested we began to supply small batches. Only to discover the noise levels were unacceptable due to the customer reducing the noise level caused by the power pack. After sourcing the origin of the noise, which was a jet of oil caused by the cushioning system we designed a micro diffuser which eliminated this and therefore lowered the noise level.

Conclusion

We have now created a cylinder which through a process of rapid evolution offers customers a higher level of functionality giving them a technical and operational advantage in the market.

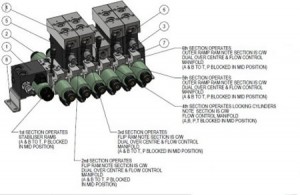

The system has been designed to make both installation and setting up as quick and as simple as possible for the body builder. The modular construction sectional valve allows all the geometric and speed controls to be assembled in the same block so saving time remote mounting in line valves and making adjustments during the setting up process making it a one man operation. All the electric coils have been specified with Deutsch connectors giving an IP69K rating against water ingress and vibration.

The system has been designed to make both installation and setting up as quick and as simple as possible for the body builder. The modular construction sectional valve allows all the geometric and speed controls to be assembled in the same block so saving time remote mounting in line valves and making adjustments during the setting up process making it a one man operation. All the electric coils have been specified with Deutsch connectors giving an IP69K rating against water ingress and vibration.

The remote control system comes with a fully comprehensive wiring loom with the male Deutsch connector and all cables are numbered to go with the corresponding coil on the valve ( see drawings below ) this in effect create a plug and play set up again saving time for the installer.

The remote control system comes with a fully comprehensive wiring loom with the male Deutsch connector and all cables are numbered to go with the corresponding coil on the valve ( see drawings below ) this in effect create a plug and play set up again saving time for the installer. Finally the end user gets the benefit of being able to operate the folding ramps with full visibility during the opening and closing cycles so making it safer and more comfortable.

Finally the end user gets the benefit of being able to operate the folding ramps with full visibility during the opening and closing cycles so making it safer and more comfortable.

Our primary design objective was to create the cushioning system and simulate this operation on our in house vertical testing system. Upon testing we discovered we required a larger cushioned pocket and therefore created an extra oil gallery which allowed the cylinder to open uniformly.

Our primary design objective was to create the cushioning system and simulate this operation on our in house vertical testing system. Upon testing we discovered we required a larger cushioned pocket and therefore created an extra oil gallery which allowed the cylinder to open uniformly.